Nature's Influence: A Laser-Cut Fruit Bowl Design Journey

| Client: | Project Duration: | Role & Team: | Year: |

|---|---|---|---|

| Homeware | 12 weeks | Product Design | 2021 |

CHALLENGE

This project aimed to create a high-quality, nature-inspired fruit bowl using laser cutting as the manufacturing process.

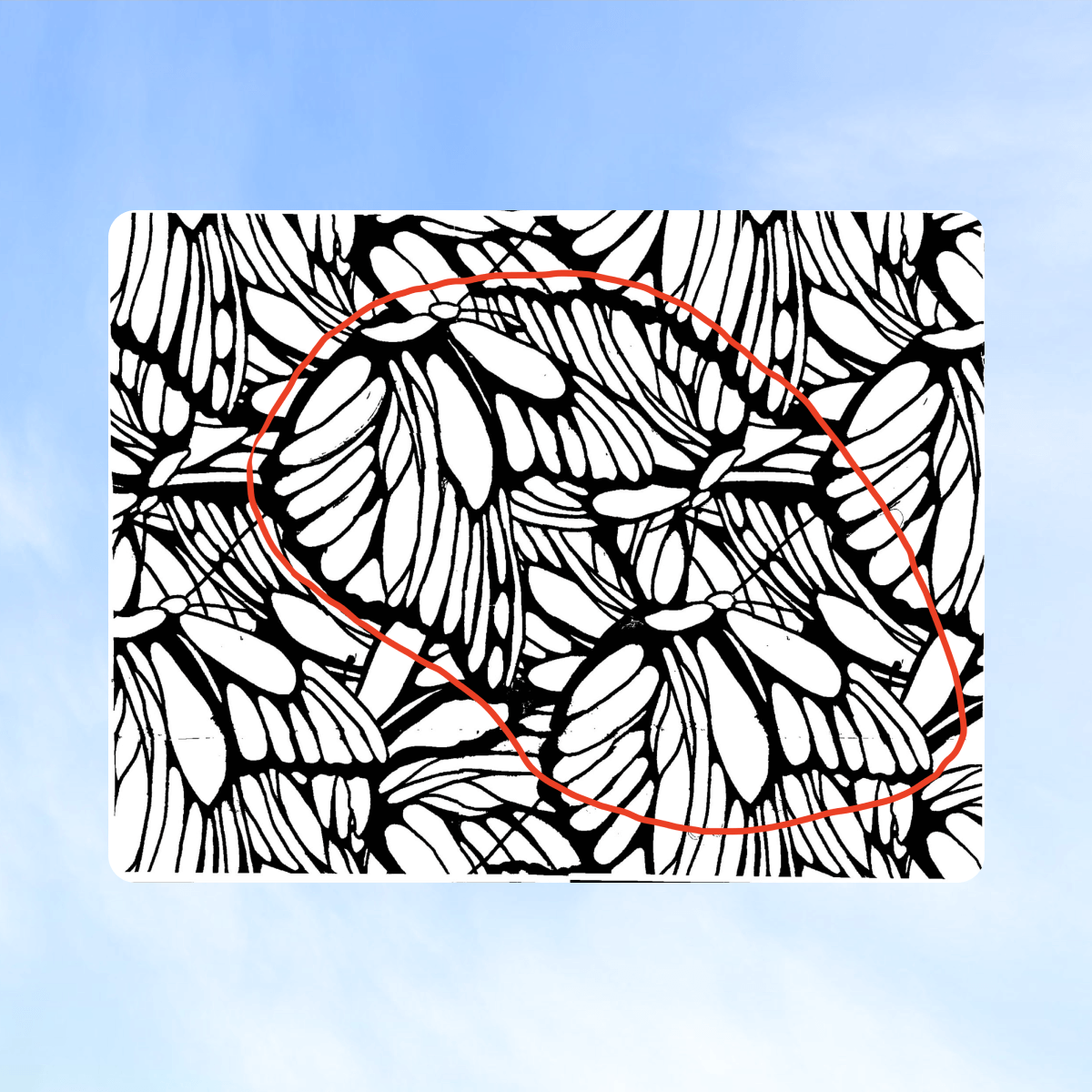

My goal was to design a product of exceptional quality and finish, suitable for a premium homeware store. This premium fruit bowl is inspired by the unique wing patterns found in butterflies and features an organic asymmetrical form. The sleek and polished design is further developed through the combination of various materials and design refinement methods.

APPROACH

50% Research

40% Hand & Digital design

40% Physical labour

Refining the design

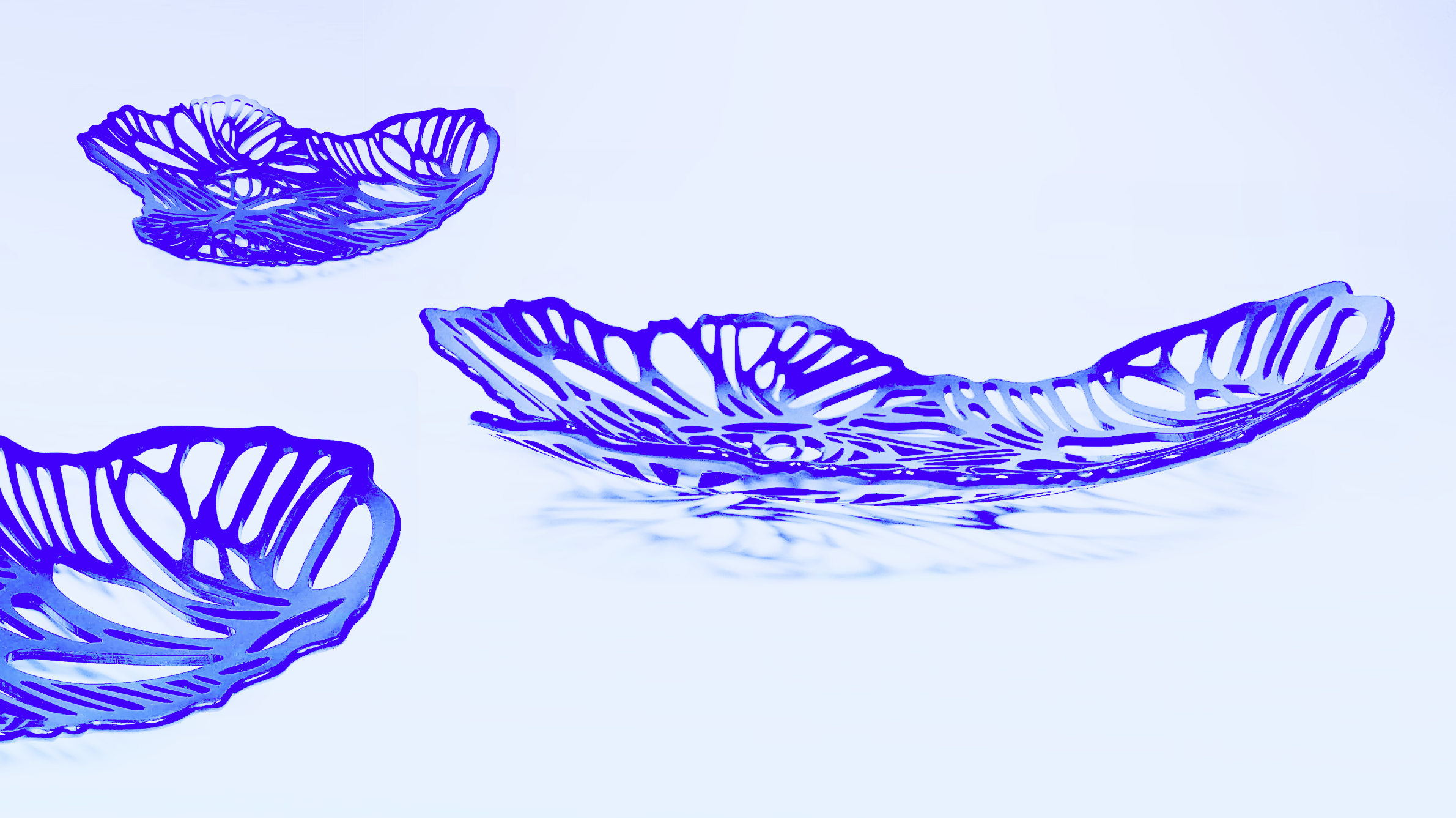

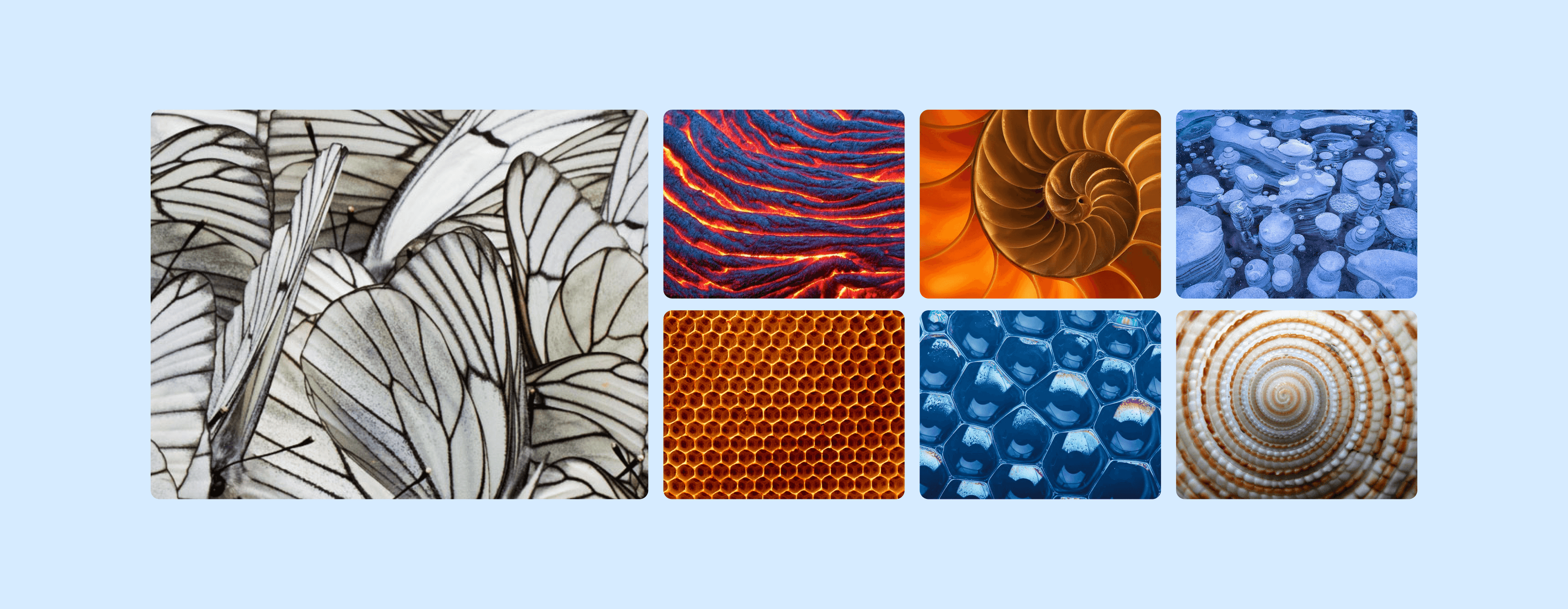

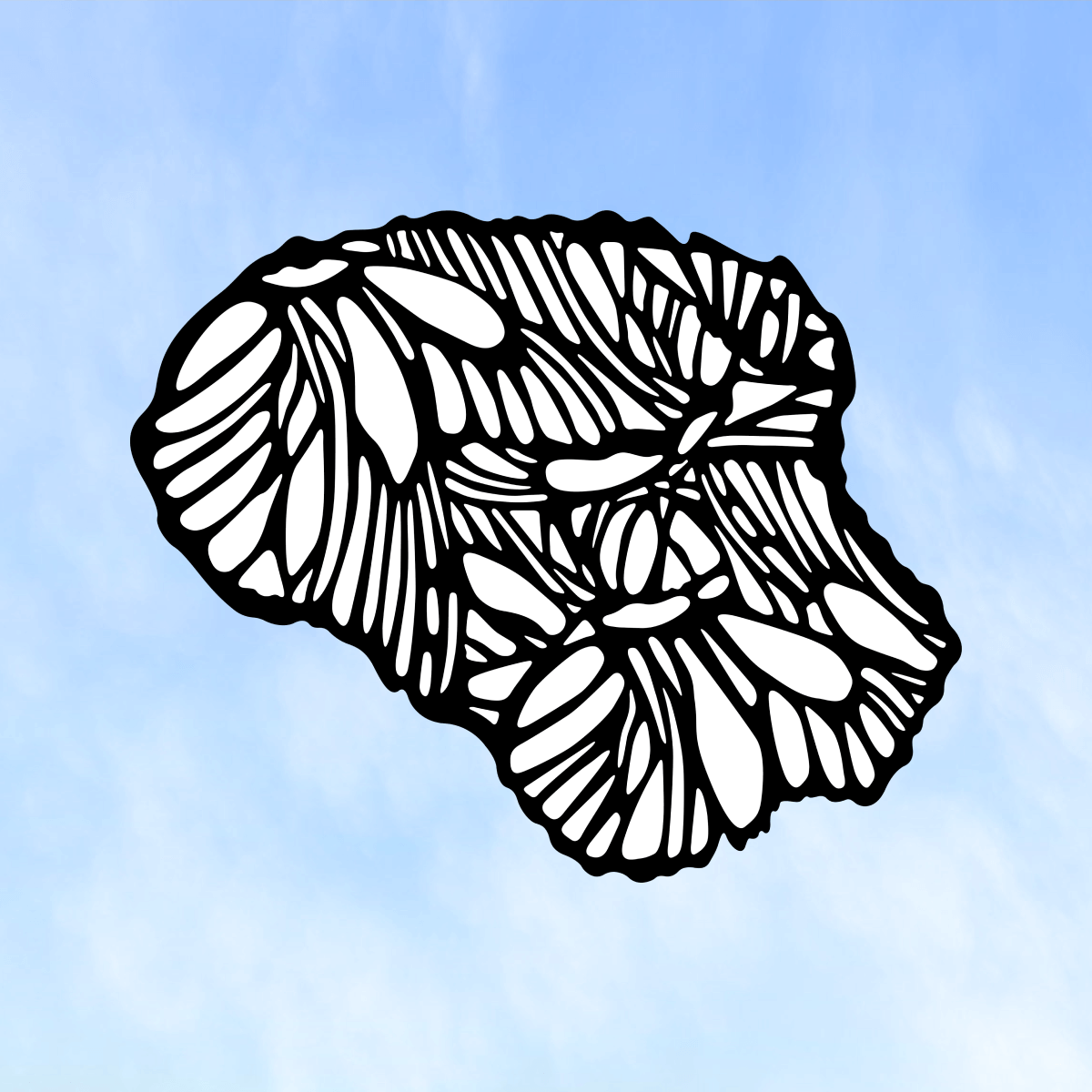

The initial sketching phase involved rapid ideation. I set out to translate the captivating shapes and patterns from our nature-inspired images into design concepts. The standout design was the butterfly sketch, characterized by its non-geometric, intricate aesthetic.

To prepare this design for further development, I upscaled it to a 1:1 scale, ensuring it could be seamlessly integrated into an A3 template. Additionally, I refined the design by adding more elements, enhancing its visual complexity. The medium of choice for this refinement was a marker, providing greater flexibility and precision during this initial design stage.

After the desired scaling had been established, the scanned image was taken into Adobe Illustrator and traced using the pen tool. This decision was rooted in the desire to minimize the number of anchor points, ensuring the smoothest possible laser cutting process.

MANUFACTURING

My manufacturing process was a meticulous journey that transformed the vector design into a polished, premium fruit bowl.

Sanding

Sanding was a fundamental step in achieving a premium finish. I began by carefully sanding the edges and surfaces, progressively refining the acrylic’s texture and appearance.

The next crucial step involved wet and dry sanding. This process focused on the top and bottom surfaces of the bowl, using wet and dry sandpaper. The purpose was to achieve a consistent matte finish that matched the edges.

Polishing

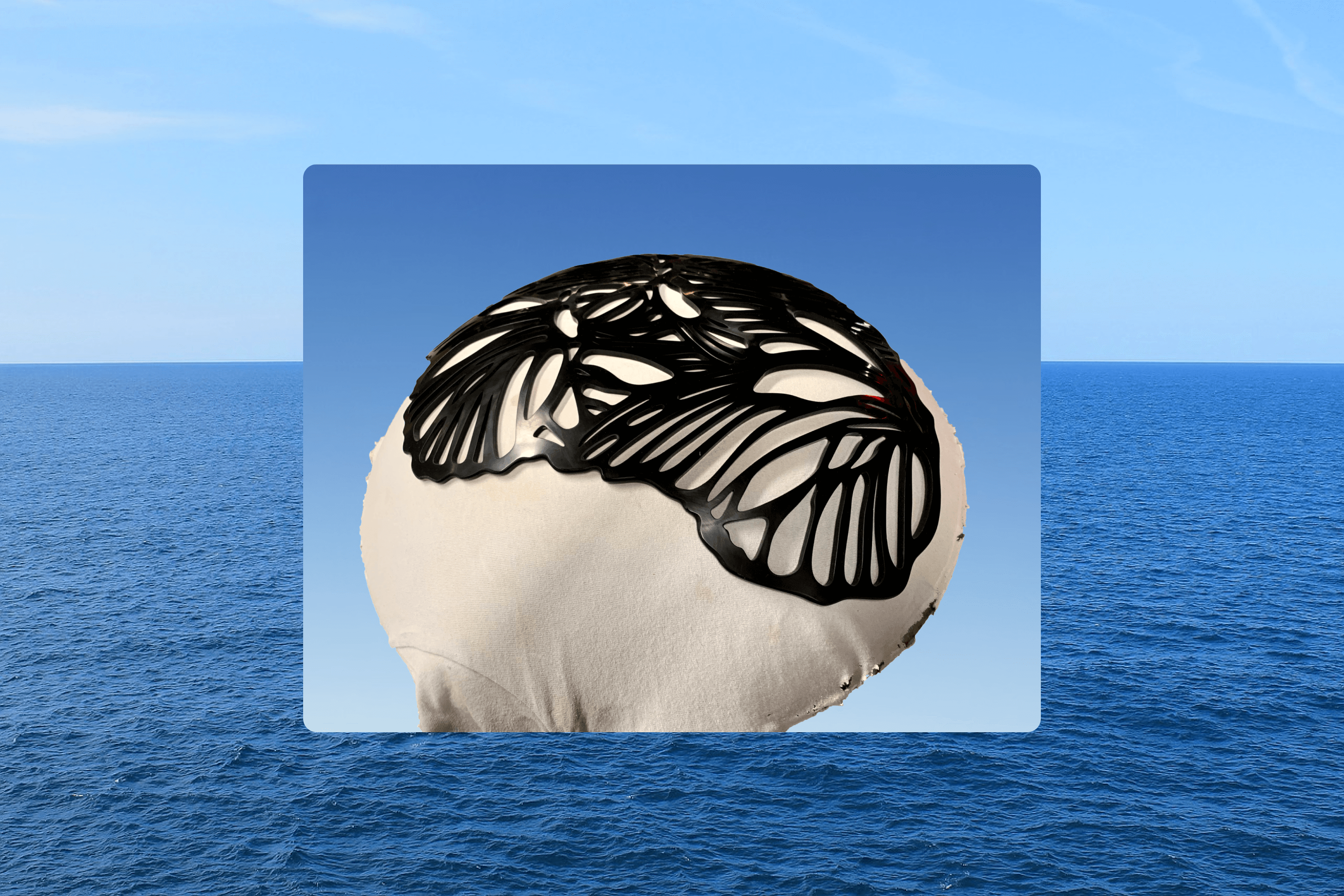

To elevate the product to a professional standard, I applied a specialized semi-abrasive polish. This step removed any remaining scratches from the wet sanding phase and imparted a glossy finish to the bowl.

Bending

The final phase of the manufacturing process was the bending step. This involved placing the flat net of the fruit bowl over a heat source and applying pressure to shape it into its distinctive rounded ‘bowl’ form.

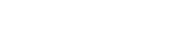

OUTCOME

Working through the entire pre and post-production from start to finish, the product is not necessarily what I expected, but in many ways much better than I had hoped. It is often difficult to conceptualise how the final product will look until it’s finished and in its final form, so considering all the doubts I had, I would say it turned out fantastic.

The combination of the overlapping butterfly wing design as well as the sleek polished finish offers a premium finish, which would give a potential buyer great confidence in actually being able to use it for its intended purpose as opposed to being a purely decorative piece!